A chevron conveyor belt is a particular type of conveyor belt that’s used in factories and plants to move things from one place to another quickly. Instead of being smooth as on a regular flat belt, the raised pattern is small arrows or “V”s. These patterns aid in holding objects more securely so they don’t fall off or slip when the belt is in motion. Consider attempting to balance on a flat tray a bunch of small balls — they’d easily roll off. The balls, however, would not move if the tray had ridges. That is the purpose of a conveyor belt chevron, to help materials from sliding down the belt when it’s inclined or traveling quickly. We’re the company behind conveyor belt chevrons that stand up to these conditions across industries and ensure that anybody’s factory can run smooth and safe each day. For high-temperature materials, you might also consider our Customized Chevron Conveyor Belt Highly Durable Conveyor Belt for High-temperature Materials.

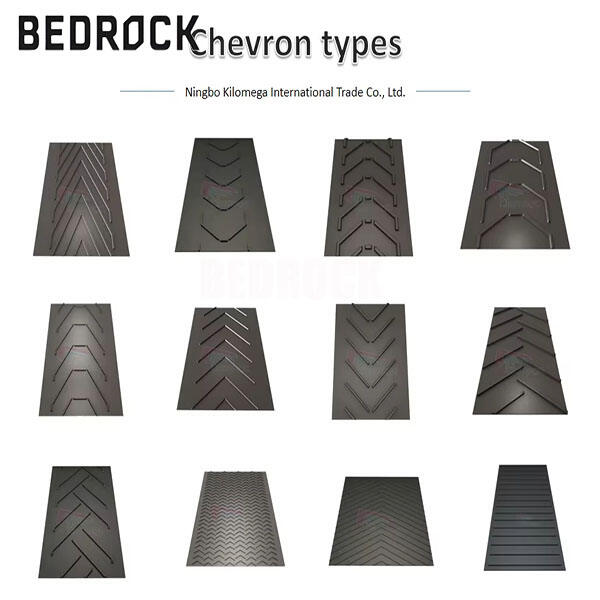

Selecting the proper chevron conveyor belt for heavy duty is not always an easy process. You're after a belt that can hold heavy stuff and last. First, consider what you’re trying to move. Is it wet, dry, rough or sticky? By various chevron belts, this will be different. For instance, if you are handling wet or slippery material, you need a belt that includes deep and strong chevron pattern. This grabs the material better, and it doesn’t slip as much. At BEDROCK, we evaluate belts of numerous chevron profiles and heights to identify the best geometry. Also look at the belt’s thickness and pliability. Heavy loads require thick belts that are manufactured using strong rubber or thicker layers of fabric inside. At times, metal components are mixed in for additional strength. One other consideration is the resistance to heat, it is oil and chemical resistant should your work place have those. Tough weather can be a little too much to ask of a belt. We support our customers with belts that last longer in rugged environments. Do not overlook the speed and angle of the belt. Steeper, faster belts require taller chevrons to protect materials. Sometimes, people choose belts based on price alone — and that’s a mistake. A cheap belt may break quickly and slow down work. At BEDROCK we believe that the contractor and professional should not suffer by paying too much for quality product at greed driven prices. Don forget that, a good conveyor belt chevron should let everything become easier and safer.

Purchasing large quantities of conveyor belt chevron can be tough if you don’t know where to buy them from. Belts are available at lots of places, but not all have been made well or lasted. If you’re after quality and value for money, it makes sense to source from a provider who knows what you really need. Many companies choose BEDROCK because we are mindful about what goes into our belts and only use high quality materials. You’ll never have to “break-in” a belt from us – we believe your wholesale belts should arrive ready to work on day one. Finally, we can also make belts for your unique machines or materials. So no wasted time with the wrong belt only to realize that it doesn´t fix things! A few sellers sell only standard belts, which may not be a perfect match for your needs. Another consideration is delivery time. We make sure to have plenty of belts in stock so you don't wait weeks for your gear. Fast delivery means your factory never stops. And, last but not least, good customer service goes a long way. If you’ve got questions or issues, you want a company that listens and helps — quickly. We do it because we want to see you succeed. Therefore, the next time you are in the market for both single and bulk chevron conveyor belts of all kinds, look no further than BEDROCK. We’re here to offer up belts that work just as hard and last just as long, making your purchase easy & simple. For heavy-duty applications, consider our Industrial Conveyor Belt Manufacturer Price, Heavy Duty Mining EP250 Chevron Rubber Conveyor Belt.

Conveyor belts with chevron pattern help move key materials up steep inclines. On the belt is the chevron design, which looks like a bunch of tiny “V” shapes and helps grab material — and keep it from slipping backward. But while these belts are durable and handy, they can face issues: A common problem we often find is when the belt wears out too quickly due to heavy or sharp materials being processed without adequate attention. Those chevron edges can also get ripped or torn, which will decrease the effectiveness of the belt. Another problem is belt misalignment. That the belt travels off center of the rollers, which can lead to edges rubbing — and wearing out quickly. When the belt slips or gets stuck, it slows down the entire process and makes labor more difficult and less safe to boot. Sometimes, dirt or small rocks become lodged in the chevron patterns and jam the belt or cause an area to stretch unevenly. That can cause rips or tears in the belt. In order to avoid these complications, the belt should be checked frequently. Check for wear, such as cracks or chevron patterns that go missing. Also helpful is keeping the belt clean. Clear litter stuck to the belt before it damages. BEDROCK provides hard wearing conveyor belts with superior chevron designs to increase the capacity and high wear on a variety of applications. If we use our belts correctly, with the right tension and alignment, many common problems can be kept from ever beginning. It is also crucial to train workers in careful belt use and report any issues promptly. If a little issue is corrected promptly, the conveyor still runs smoothly and it saves money. Routine inspections and good housekeeping make conveyor belting last longer and function best every day.

The construction of the conveyor belt can be devided into three parts.: The shape and structure of the conveyor belt, especially the chevron pattern, determine the actual capacity of a conveyer system. When sands, gravel and small rocks need to go up a hill or incline, people may not know where else to look except on a flat belt. This is because of the possibility that the material can move backward and in such case the operation becomes slow and dangerous. The chevron pattern solves this issue by incorporating raised “V” patterns to the surface of the belt. These shapes function as little walls that keep the materials inside. As the belt runs, the chevron pattern compresses the material and forces it to move forward without letting it slide back. This will, inturn, make moving materials easier and faster. The type and size of chevron patterns are meticulously selected by BEDROCK experts to work well with various materials and pitches. Taller chevrons are good for steeper slopes, like on a belt, while smaller ones do the trick when the slope is gentler. The proper design also aids in saving energy as the belt isn’t required to work as hard to keep materials moving. That means machines consume less power, and that’s a good thing for the environment as well as for saving money. Another advantage of the chevron design is that it keeps the materials clean and avoids spillage. While materials remain on the belt, there is less mess and waste.” This helps keep the work area cleaner and safer. And more generally, the chevron is not just about looks — it makes a huge difference in how well and how safely materials flow. BEDROCK’s smart chevron conveyor belts let you run your business smoothly and at low cost.

How to Kept Conveyor Belt Chevron for Long-Term Obtain How to Preserve Protect0ns5 Rubber Conveyor Throughout constantly use, the_TechTongdian Whenever using it.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.