When you’re using machines that transfer hot materials, the type of conveyor belt you use is very important to the performance of your equipment. All belts do not withstand heat well. If the belt overheats, it may melt or weaken. Which is why companies such as BEDROCK offer heat resistant conveyor belts. These belts consist of materials that can withstand high temperatures without deteriorating. The right belt makes machines run better and last longer. This is especially important in sectors such as metal, glass or food processing where things run quite hot. The type of belt material utilized can prevent problems before they occur, thus saving time and money

It’s not always easy to decide which heat resistant conveyor belt material is going to be best. You’ll want to consider how hot the belt will become. For instance, if it’s transporting molten metal or hot glass, the belt can’t melt from exposure to very high temperatures. BEDROCK provides belts constructed from various materials, all with their own advantages. Certain materials can withstand heat, but may be weak. Still Heat resistant conveyor belt others are very durable, but they only withstand moderate heat. And knowing exactly what your machines need can help. Also, the environment matter

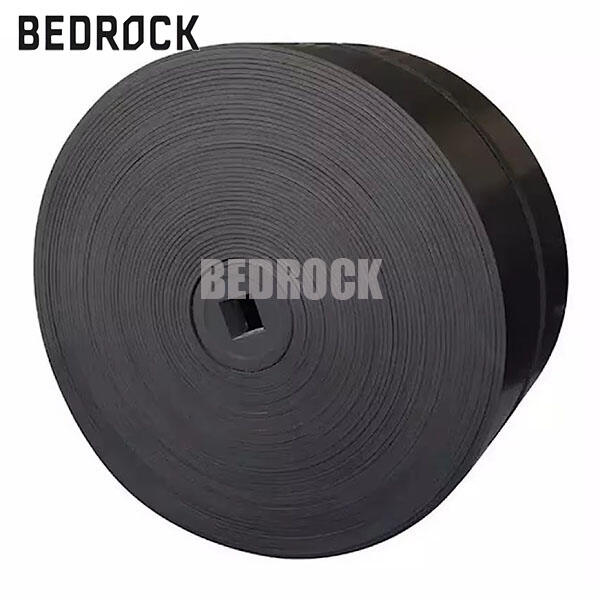

Heavy-duty tasks require heavy-duty belts that aren’t going to quit when they get hot. BEDROCK takes as much care when doing that. One common material is that of an aramid fabric. This stuff can stand up to heat and is super strong. It barely stretches at all, so it keeps belts tight and trustworthy. Fiberglass fabric is another common selection. Fiberglass can withstand extreme temperatures without burning or melting. It is great for super hot jobs, such as moving glass or ceramics. Belts are often layered with rubber or silicone on top of these fabrics. Silicone rubber can withstand heat and also allows for the belt to remain supple, assisting it in lasting longer. At times, even special metal wires may be present in the belt. These are wires that help to keep Heat resistant conveyor belt everything in place and help make the belt stronger. BEDROCK’s belts often combine them to maintain all the good properties: being heat resistant, sturdy and flexible. The thickness of the belt also counts. Thicker belts can support a heavier load and longer life, though they may have less flexibility. Thin belts ride better but can break down faster if you have too much heat. It depends on the work, a choice you make — left or right? For instance, in steel mills, belts must be hardy and heat resistant since the metal is both extremely hot and heavy. In the food processing, a belt may not have to support much weight, but it must resist various temperatures from ovens or steam

To prevent these difficulties, it is of utmost importance to select the proper heat resistant conveyor belt material such as that from BEDROCK. BEDROCK belts are strong, heat-reistant and last longer because of what they are made from. It is also critical Heat resistant conveyor belt that the belt be cleaned periodically by wiping it down to remove dirt, grease/oil and dust. If you melt it, keep in mind that a clean belt is a sticky belt and a better working one

Proper installation is also key. The belt has to put on conveyor of the system without being forced and running smooth. You can address this if you have the right tools (and follow instructions). Finally regulating the temperature where the Heat resistant conveyor belt is located can help it wear less. Selecting heat resistant belt cover rubber can greatly reduce system’s maintenance costs, as you may need to service or replace the conveyor belt less frequently

A typical place where BEDROCK belts are deployed is steel mills. Because of this, red-hot metal flows from one machine to the next in these factories. That metal can be red hot, and the conveyor belts must handle it without themselves being Heat resistant conveyor belt destroyed

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.