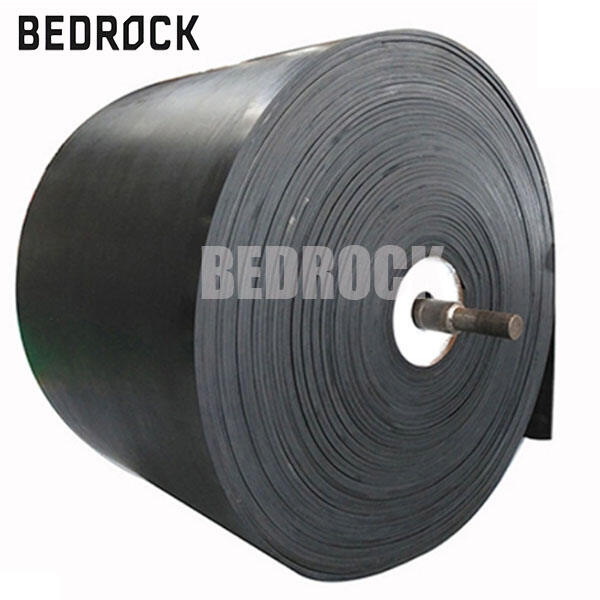

A concrete mixer belt is a very crucial component in the concrete mixer machine. The belt is what turns the power from the motor into revolutions of the drum, where the concrete sits. It is pretty simple, however without a functioning belt the mixer will not spin correctly and the concrete will not mix evenly. We are a long time trusted and established manufacturer for the concrete industry. When you trailer your toys across country, drive to work on the the roughest terrain or build those roads, houses and bridges – having a belt that never lets you down is more than just an added bonus – it is an absolute necessity. The BEDROCK steel cord conveyor belt may look tiny, but it works its tail off every single day. If it breaks, or if the belt slips, the whole mixing operation stops — and that can hold up construction projects. So understanding how these belts operate and how to maintain them can save a lot of hassle.

What You Need to Know about Powder Coating Construction Projects? There is no doubt that construction tools and parts must be extremely durable; they need to last, and on a budget! The concrete mixer belt is likewise, another essential component in many construction machines particularly the concrete mixers. This belt assists the movement of materials within the mixer enabling it to mix properly concrete. Wholesale concrete mixer belts may give you the best value for your project because you’re getting several of them at once (often, at a cheaper price per belt). Going bulk will help you save money, which is essential if you have a big job or several machines to take care of.

Your wholesale belts from trusted brand like BEDROCK are built with a long life and solid performance in mind, meaning you have to buy new belts less often, so you save time and money. That incline conveyor belt has the advantage of minimizing downtime on your construction site since the machines can continue operating without constantly needing repairs. When machines go down, it slows everything down and can add up to more money. Getting tough belts from wholesale supplies makes your project run smoothly.

If you would like a brand-new concrete mixer belt and will need to discover the correct part that’s affordable, be sure to select a genuine, durable and hardworking belt. There are a lot of look-a-likes on the market (and other quality knock-off belts), but most aren't to my standard. The use of these low cost belts can cause your concrete mixer to loose money in downtime, and even cause other belts on your equipment to last less than they should. You don’t want to get scammed, and you can also give yourself the right sort of peace of mind by learning how to recognize a real concrete mixer belt.

The next thing you need to examine is the quality of the belt material. Once you have tried our premium molded rubber mixers you will never go back to scrap truck Shido mixer covers! You won’t find real cement mixer belts mistress after belt not poisoning everything it touches Its personal without a name its the original with NO VARIATIONS. These mining belt conveyor from BEDROCK are manufactured with multiple layers of sturdy rubber and tough fabric, helping keep them together under heavy lashings. Low-quality belts may appear thin, soft to the touch or contain rough edges. If you can, feel the weight of and handle the belt. A real belt tends to be heavier and more sturdy.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.