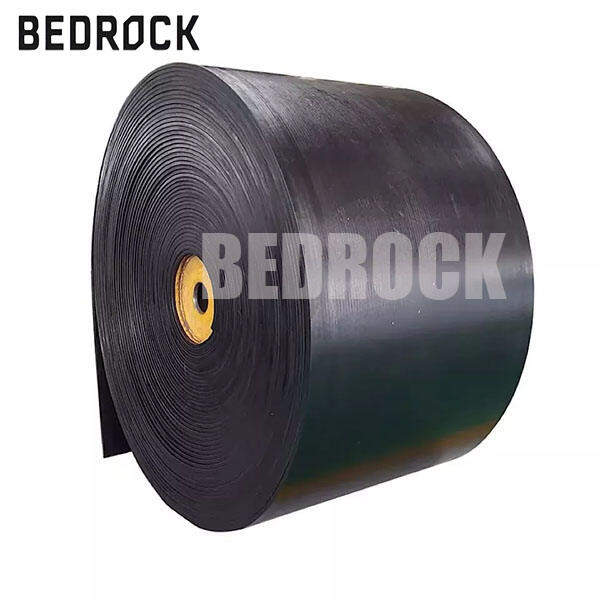

Fabric conveyor belts are invaluable tools in many factories and storage facilities. Like, these belts that help move stuff from one place to another but you don’t need people to carry it all the time. They are constructed with multiple layers of fabric that provide both strength and flexibility. Fabric belts, unlike metal or plastic belts, can bend around rollers more readily and have a lighter footprint, consuming less energy. Fabric conveyor belts are routinely trusted by a wide array of industrial business and can keep your work going smooth with products ideal for virtually any situation. If you’ve ever seen a fabric conveyor belt, you know in your heart of hearts that it is covered with a surface that grips objects so they don’t slide off. It’s sort of like a moving walkway for packages, boxes or raw materials. Companies like BEDROCK construct these kinds of belts to be durable, stout and long lasting and work-rugged (even though worn on an every day basis) for hard, wide-ranging jobs such as construction. It’s a cost saving for businesses, too, because they don’t have to repair or replace belts that need it all the time.

Choosing the best fabric conveyor belt can be a challenge, particularly if you do not know what to look for when buying in bulk and shipping them to your place of business. All belts are not created equal, and quality counts. First you should examine the type of material is in the inside. Cotton or polyester layers under the leather are found in some belts, but the better ones instead feature fabric designed to be heat- and wear-resistant. And what if your belt breaks or tears on a hectic day, which slows everything down and costs you money. So, a good strong fabric core is crucial. Then inspect the surface of the belt. It needs to hold things snugly, so they don’t slide as the belt moves quickly or up an incline. Some belts are smooth, some have a rough or textured feel based on what you need to carry. If your wares are heavy or have sharp edges, you need a belt that can take a lot of punishment. Thick and stiff quality is also a big factor. A thick belt can be more durable but may not fold well around rollers. In contrast, a narrow belt is pliable but may lack durability. A balance of this and that is vital. BEDROCK belts are specially crafted with this balance in mind. Also look for the belt to be resistant to water, oil and chemicals if your work environment includes these. Occasionally, belts get wet or dirty and if they absorb liquid or chemicals, they will break down quickly. Better to pick belts that are treated not to resist these things. Warranty and certificationAnything else you’ll want to look for. A quality belt will be warrantied and safety or quality certified. Finally, the price is important, but don’t choose on price alone. You’ll pay a little extra for a trusted brand like BEDROCK, but you receive a belt that fights just as hard and lasts even longer. Purchasing in bulk may save money, but quality must not be compromised. As you can see, a cheap belt that wears out fast can get pretty expensive over time.

You may find yourself scratching your head while trying to found the proper place from which to purchase fabric conveyor belts in bulk. There are a lot of sellers who will have you believe they carry the best belts, but you should be cautious. Firstly, find the suppliers that is specialized in fabric conveyor belt instead of some other general products. And experts know what industries use these belts, so they can guide you to a better solution. Being one of trusted fabric conveyor belt suppliers, we have decades-long experience achieving successful results for our clients. Ask how they make when you actually contact a supplier. Are they a maker of the belts or simply resellers? Generally speaking, when a company has their products made specifically for their use, the overall quality and support of that product tends to be better. Also, see if they do customization. Occasionally, your business may require the belts in custom sizes, special thickness and with specialized coatings. An excellent supplier, such as BEDROCK can offer you these choices. Smart to order some samples before purchasing a lot of belts. That way, you can feel the strength, grip and flexibility of the belt. Yet another key is delivery and support of services. You’re buying wholesale so you are getting many belts and that can fuck with shipping. Find businesses who are proactive in fulfilling orders and servicing issues after the sale. Reliability can be implicit in reviews and customer feedback. If other people say they had a positive experience with a provider, that is an encouraging sign. Keep away from suppliers who do not answer questions well or don’t know much about their products. Finally, price is of course a consideration, but don’t let it be the only one. The lowest bidder may have poor-quality belts that snap easily, causing delays. BEDROCK is dedicated to quality and customer service that makes it all the more appealing for businesses to depend on their fabric conveyor belts. Ask me that's Reliable source to save yourself the hassle and keep operations running, know what you need. Also, consider looking into options like Sidewall Conveyor Belts for enhanced material handling.

Fabric conveyor belts are invaluable in many industries where heavy items need to be transferred from one location to another. These belts are reinforced with tough fabric layers to resist wear and tear, so they can hold up under the weight of heavy loads without breaking. At BEDROCK, we are proud to know our fabric conveyor belts can stand up to the most demanding applications every day. The layers of fabric inside the belt are like the bones in a body, they give it shape and strength. So you have a belt that can stretch a little bit, but not so much that it won’t be able to hold really heavy things such as rocks, coal or large boxes.

The fabric conveyor belts by BEDROCK also have resistance against heat and water. A lot of heavy-duty tasks take place outdoors, or where the belt could become wet and hot. The material we work with withstands these rough conditions, so the belt continues working even in bad weather or tough work. And, since we can make our belts in a variety of sizes and thicknesses, today we help outfit any company in the world with the right one. It is with good reason – strength, flexibility, and dependability – that these belts are the best selection for long distance conveyors. Additionally, our Flat Belts offer another versatile option for various applications.

Another aspect of maintenance involves ensuring the belt is running in the proper position on the rollers. If the belt shifts too far from one side to the other, it is more likely to rub against machine parts and wear out. According to a request that has been filed, having the belt alignment checked every seven days can help prevent this. Additionally, your belt should have the perfect tension – not too tight and not too loose. If it is too tight, the fabric inside can be stretched and weakened. If the belt is too loose, it can slip or get caught in components.

Fabric conveyor belts, even those with the strongest strength, suffer over the long run. That’s fine, because they all work hard every day. At BEDROCK, we know what the most common problems are and we have easy solutions to avoid them and keep your belt at work without hurting it. One of the common problems which having a sharp things on your belt will causes damage to it. Belt fabric can also be cut or torn by hard or sharp particles. You can prevent this by using special belt covers or guards that protect the surface of the belt. BEDROCK makes these protective covers that enable the belt to be out of harm's way from sharp edge. For added durability, consider our Rough Top Conveyor Belts.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.