Not all belts are created equal when it comes to conveyor belts. The right conveyor belt can make all the difference on the site. BEDROCK understands that a solid, functional belt is your indispensable companion and the only flexible, durable tool you cannot afford to be without. Whether you are handling heavy grates or tiny parts, the appropriate belt should hold up to the task without wearing out quickly. Some hold up better than others; some are prone to slipping or snapping. Buying a belt that suits your style involves more than just selecting the cheapest option. That involves thinking about how resilient the belt is, what it’s made of and how well if fits your machines.

Choosing the appropriate conveyor belt is a very important task, and purchasing the wrong one can affect such factors as productivity or downtime. It may be tempting to go for the lowest price, but that can actually cost you more down the line when belts break or work slows down. First, consider what your business requires on a daily basis. Do you transport heavy cargos such as metal parts, or light things like food parcels? This has an influence on the strength and construction of the belt. BEDROCK belts are available in lots of designs, so you can pick the one that complements your work. Also, examine the width and length of the belt. Too tight or too short can’t fit your machines well, and also do some harm. Some have grippy surfaces for holding slick stuff, while others are smooth to keep faster moving things from getting dusty. Ask yourself how frequently you want to replace your belt. While it may cost more to purchase initially, a good wholesale belt will see to it that you save money over time as they last longer than others. Oh, and do not forget temperature and environment. If your business operates outside or in a cooler environment, the belt should perform at those temperatures without cracking or freezing. BEDROCK is paying attention to all those factors, so you get a belt that works hard for you. For one business, the change to a stronger BEDROCK belt put an end to machines breaking down every five days. That allowed them to avoid spending time and money. So, when selecting wholesale belts, consider more than cost; the strength, width and surface of a belt -and its environment. The proper belt is what makes your business get along smoothly. If you're interested in high-performance options, check out our EP Conveyor Belt – Heavy Duty, Wear-Resistant, Heat-Resistant for Industrial Material Handling.

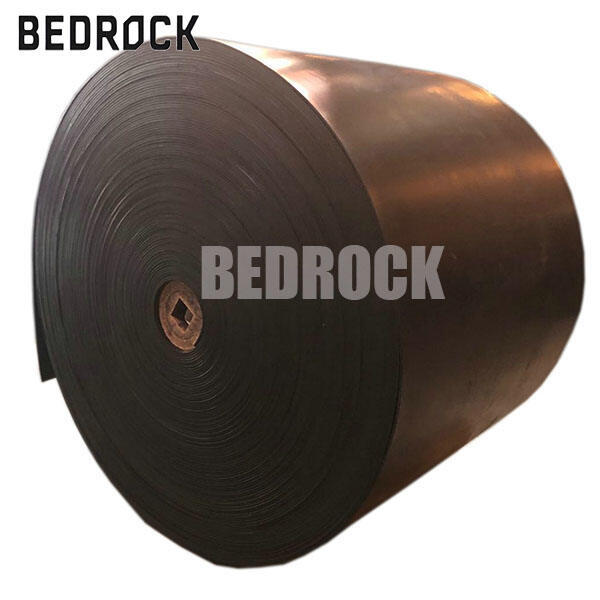

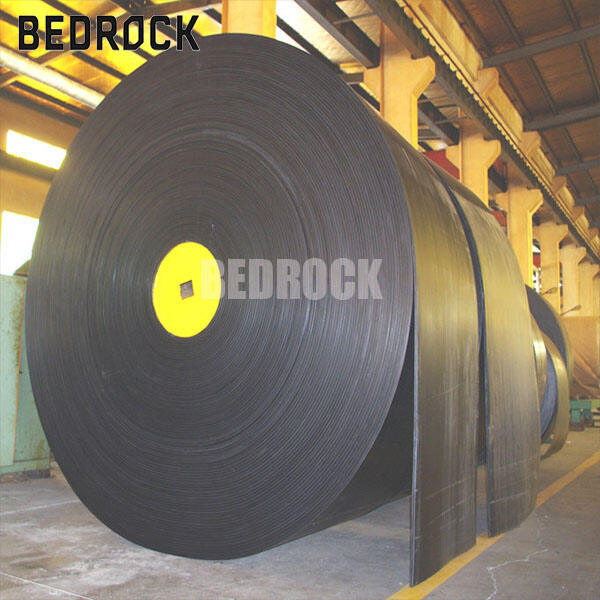

Durability is all about how well a conveyor belt takes an beating in the long run, day to day, year after year. For strenuous use, the composition of the belt is of even more concern. To prevent cuts, heat and stretching, BEDROCK incorporates special fabrics and rubbers. One of the popular core materials used is polyester or nylon fabric which provide the composite with strength and flexibility. Some belts even have steel cords on the inside for added force when hauling super heavy stuff, like metal sheets or bricks. The outside also matters a great deal. Rubber is commonly used because it has good traction and resists wear. Some rubbers are built to withstand oil, chemicals or heat, so the belt holds up longer in harsh environments. For instance, a factory transporting its hot parts from their molds uses a belt that resists the heat and does not tear or melt when these materials are transported. Should the belt be used outdoors, resistance materials prevent damage from sun or rain. For tones off the beaten path, BEDROCK often mixes multiple materials to form a belt matching exact needs. It’s not only a matter of being strong, but also one of remaining flexible enough that the belt moves easily over rollers and pulleys. A belt that is too stiff will break or wear out prematurely. What I can say is that, in my experience, finding the right materials is no different than picking out what shoes to wear on a long walk: it’s comfy or you’ll be limping. A conveyor belt should be strong enough to bear the weight, and it should have a material tough or rigid enough to withstand rough surfaces/edges and the elements. BEDROCK’s meticulous choice of its fabric, cord and rubber layers ensures that our belts last all day, every day - keep up the #workhardwearwell even when others fail. This means your business does not stop and you can rest easy that your machines are protected. For those in need of durable solutions, consider our High Quality Cheap Price Rubber Conveyor Belt 4 Ply 800mm Belt Flame Resistant Ep Conveyor Belt.

There is a lot of care needed when you are buying conveyor belts in bulk or wholesale. Conveyor belts are how things move from one place to another in many factories and warehouses. The wrong kind can get you into big trouble if you buy them. One frequently encountered issue is purchasing a belt that’s too weak for the task. For instance, if you require a belt to keep heavy parcels straight, but the kind of the belt is not strong enough, it will wear out and break soon. That will halt construction and cost more money to repair. Another is purchasing belts that simply do not fit the machines correctly. Sizes and thickness of conveyor belts vary. From there, a too big or too small belt will also not work as well and might even cause harm to the machine. It’s worth taking careful measurements before you buy one. People are sometimes selling belts that don't even feel real. Cheap belts may be stylish and that’s about it, since low-cost materials like rubber or fabric can make them up. These belts do not have much longevity and can become safety hazards, as they may slip or rip too easily. Some conveyor belts are also not resistant to heat or water. If the belt is to be worn in a hot factory or outdoors, it must stand up to such environments. Otherwise, you’ll wear through the belt tbh. Ignoring the supplier’s name is another problem. Purchasing from a reputable company (like BEDROCK), helps eliminate so much of that frustration, since we provide high quality conveyor belts that last longer and perform better. Finally, don’t request samples or test the belts before purchasing is also asking for trouble. You’re smart to want to try a couple of belts first, to see whether they strike you as working well in your machines and under your conditions. In other words, shun the substandard belts, undersized belts and inferior quality material, not to mention unscrupulous sellers dealing in wholesale conveyor belts. Checking these things take a few minutes but will ultimately save money and headaches down the road.

The resource you can keep in mind to look while looking for real, good quality conveyor belts in wholesale markets is difficult to find but with few easy tips you will know that where from your purchasing right belt. Carefully inspect the material of the belt initially. The best conveyor belts are constructed from tough rubber, long-wearing fabric, or hardwearing plastics that do not easily break. You may be able to ask the seller about what type of materials were used, and some sellers offer certificates that will verify quality. We never keep our belt materials in the dark because we want you to trust your... belts. After that, inspect the belt’s surface and width. A proper conveyor belt – firm, smooth with no cracks or bubbles. Belts that are narrow or uneven may be an indication of poor quality. You can also flex the belt slightly to determine if its flexible but not soft. Another a crucial sign of the belt is its weight. Really good belts tend to weigh more because of strongener on the inside. If a belt seems too light, the construction may be less robust or it may contain cheaper components. You can also inquire with the seller about how well the belt functions in heat, water and chemicals. Conveyor belts have to work in some of the most challenging environments, so superior belts will feature special protection to help them last. When you do want to buy from wholesale markets, try asking for samples or small amounts first. Try the belt on your machine to know if it fits great and last long. Also, check the seller’s reputation. A reputable seller like BEDROCK will do warranties and good customer service. They help you select the right belt and troubleshooting any problems. Lastly, search for belts that adhere to industry standards and certifications. These indicate that the belt has undergone testing for quality and safety. Following these basic steps will enable you to procure true high quality conveyor belts which function well and last long.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.