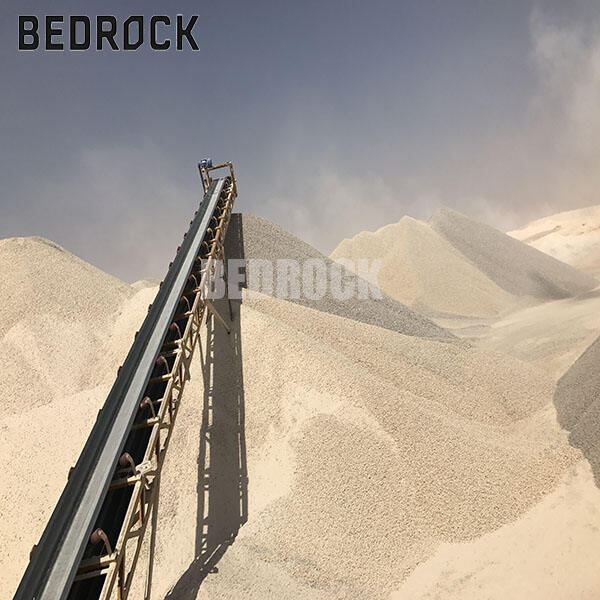

Sand conveyor belts are one of the most popular tools used in a variety of different kinds of businesses to move sand quickly and safely from one location to another. They are like giant, fat belts that roll over wheels and carry sand away. These belts enable workers to safely lift without having to carry heavy loads by hand, providing faster and less labor-intense work. Sand conveyor belts are used in locations such as mining sites, construction areas or at factory facilities where sand needs to be moved over both short and long distances. Now and then, the sand may be very coarse or heavy, in which case the belts need to be strong and durable. There are, however, such things as sand conveyor belts that can handle the challenge. With the right belt, businesses can save time and prevent pitfalls such as breaks or jams that slow down work

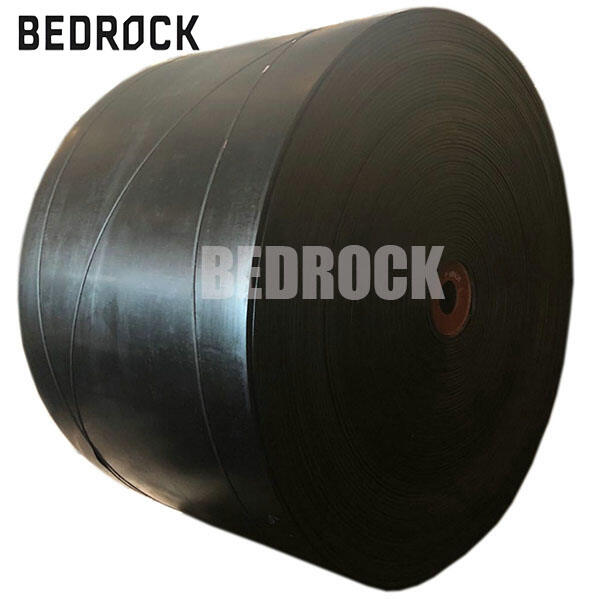

It is not easy to find the good sand conveyor belts in bulk. There are a lot of different companies that sell conveyor belts, but not all of them were made to last and not all of them would work very well with sand. If you need to purchase belts for a significant project, it’s critical that you find a supplier with experience. BEDROCK has long experience making belts that perform well on sand and other coarse materials. When you purchase BEDROCK belts wholesale, you buy a lot of belts at once and save. Plus, you’re doing it with belts that have been tested to take on demanding work. If a mining corrosion-resistant conveyor belts company needs hundreds of belts to move sand and rocks, for instance, buying from BEDROCK wholesale assures they are getting belts that won’t easily tear or stop working. Some less expensive belts wear out quickly and can prompt delays. But BEDROCK’s belts are constructed with specialized materials that can withstand wear and tear. Also consider delivery and support. AND AT BEDROCK, IT HELPS CUSTOMERS OBTAIN WHAT THEY NEED WHEN THEY NEED IT SO THAT PROJECTS ARENʼT DELAYED. And customer service is available to answer any questions or help get problems fixed in a hurry. Purchasing from a known source like BEDROCK reduces anxiety and earns bigger rewards for the big boys. So, if you need bulk SBR belts and aren’t already buying from BEDROCK, make the smart choice.

The sand conveyor belts in the mining industry are much stronger and tougher. Mining is dirty work and belts can become damaged from sharp rocks, heavy sand loads and bad weather. BEDROCK ensures that their belts are packed with several crucial elements to make it through these harsh conditions. A major factor is the material of the belt. BEDROCK uses heavy rubber and stronger materials that are not likely to break easily. This allows the belt to deliver heavy sand without tearing or prematurely wearing out. Resistance to heat and chemicals is another characteristic. Belts may be dealing with hot temperatures and contact with chemicals in mining, so belts must keep workers safe and be sound enough to work. The surface of the belt is also engineered to grab sand and not let it spill off. That is, the sand flows more or less freely and without leaving much behind. The belts have sealed edges to prevent dust and fine sand grains from getting inside and damaging the insides of the belt. “We test it on belt, under ground in actual mining conditions to make sure it can hold up with gassy coal every day. Other times belts have to be flexible in order to curve around corners or undulate over hills, so BEDROCK designs them to flex without snapping. Moreover, the belts must be easy to attenuate because dirty belts are themselves problematic.” BEDROCK’s belts are also water and dirt resistant to help your ride last. In a mine, a broken conveyor belt can effectively stop operations for hours or days, leading to loss of money. So if you slip a burly belt from hard rock transportation conveyor belt BEDROCK around your waist, you’ll have fewer breaks and just better work flow. So it’s no surprise so many mining companies rely on BEDROCK belts to power through the work without throwing in the towel

The sand conveyor belts are among the really useful equipment being employed in bringing the sand from one location to another. But like all machines, they can go wrong now and then. Understanding these issues and how to correct them can help you save time and money. Belt slipping is a common problem with sand conveyor belt. It occurs when the belt no longer moves smoothly along the rollers or pulleys. If this doesn’t happen, slippage can occur, leading to delays and the risk of belt damage. To resolve this, you can test the belt tension and inspect the rollers. Occasionally the belt slipping could be resolved by adding more tension in the belt or having the rollers cleaned.

If you require a lot of sand conveyor belts for your business, then you should seriously consider purchasing them in bulk. When you purchase in bulk, they tend to cost you less per belt, which saves your budget. If you need to purchase sand conveyor belts in bulk, it’s crucial that you find a supplier that charges reasonable rates and provides quality service. BEDROCK is the cost-effective sand conveyor belt for use in tight areas! Their sand transportation conveyor belt belts are durable and lasting, offering great value for money.

It is important to choose the correct sand conveyor belt when dealing with challenging environments. Harsh environments are those where the weather is cruel or the sand is coarse and burly. The belt you choose should be durable and engineered to withstand these rough conditions. The BEDROCK company makes sand conveyor belts that are especially good in hard places. Here are the things to consider when searching for belts with harsh high-capacity conveyor belts environments in mind.

Second, the belt’s resistance to heat and cold matters a great deal. Temperatures can fluctuate a great deal in parts of the extreme landscapes. Thin belts may crack or turn too soft if the weather is very hot or cold. BEDROCK builds its belts to stay stiff even when the temperature mixing plant conveyor belts fluctuates. This prevents the belt from breaking and ensures it is also functioning properly.

With an established local leadership team and service network in Saudi Arabia, we offer end-to-end support—from product selection and installation guidance to ongoing performance tracking—ensuring prompt response, clear communication, and minimal disruption to your operations.

We measure our success by your operational outcomes. Through continuous follow-up, optimization, and a commitment to total value, we build strategic partnerships that help you reduce downtime, improve efficiency, and achieve sustainable growth together.

We don't just sell products — our experienced team in Saudi Arabia provides customized conveyor system recommendations based on your specific working conditions and industry challenges, ensuring optimal fit and long-term performance.

Backed by 16 years of specialized R&D and experience in national-level research projects, we develop conveyor belts that exceed industry standards in critical areas such as high-temperature and flame resistance, delivering reliability under the most demanding operational environments.